Next-generation portable devices for rapid testing of key micronutrients and food quality. iCheck Modular offers a connected, cost-effective, and versatile solution for on-site quality control—redefining how fortification and food quality is monitored globally.

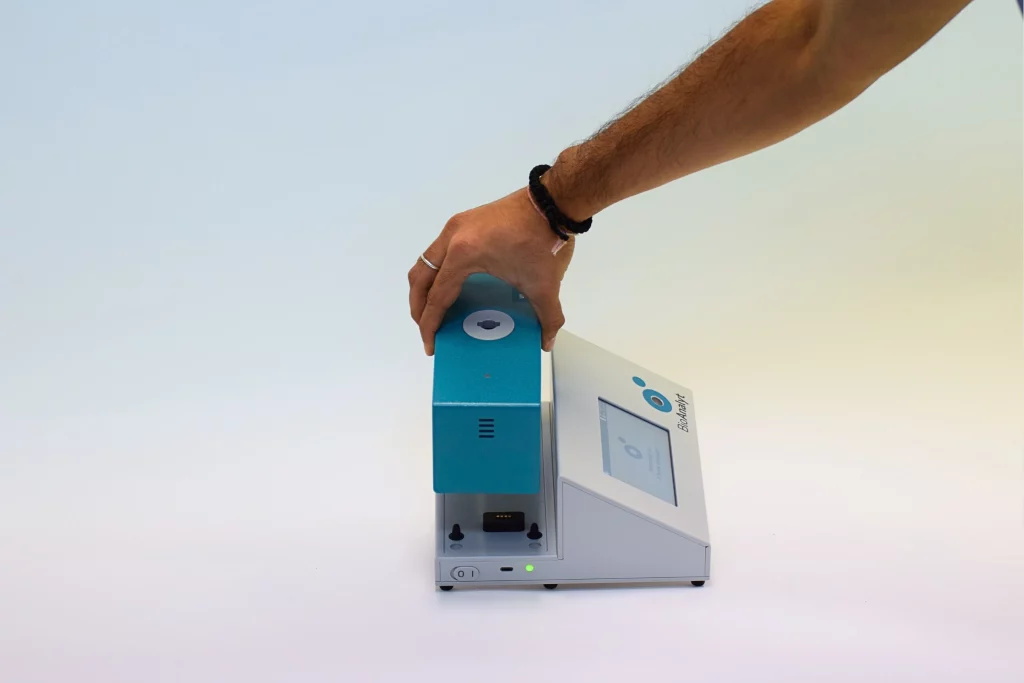

The iCheck Modular is an innovative analytical device developed by QuImpact in partnership with BioAnalyt, with the support of the Gates Foundation. Designed to revolutionize food fortification and quality monitoring, this portable, all-in-one solution combines advanced technology with unmatched versatility. It enables rapid, cost-effective, and accurate on-site testing of key micronutrients and food quality parameters, providing actionable results where they are needed most.

The iCheck Modular is an innovative analytical device developed by QuImpact in partnership with BioAnalyt, with the support of the Gates Foundation. Designed to revolutionize food fortification and quality monitoring, this portable, all-in-one solution combines advanced technology with unmatched versatility. It enables rapid, cost-effective, and accurate on-site testing of key micronutrients and food quality parameters, providing actionable results where they are needed most.

The iCheck Modular serves as a cutting-edge platform that supports the integration of a wide range of analytical parameters for assessing nutritional value as well as food quality and safety. Initial capabilities include testing for vitamin A in edible oils and fats, peroxide value for oil quality, iron and vitamin A in fortified foods such as wheat and maize flour, fortified rice kernels, and condiments. Additional capabilities, like carotene in root vegetables and iodine in salt, will follow. Over time, the device will expand to include nutritional parameters for other food vehicles and safety parameters critical to public health. These new functionalities will be seamlessly added through remote software updates or by incorporating an additional measurement unit, ensuring adaptability to future needs.

Food fortification remains one of the most effective interventions to combat micronutrient deficiencies, yet the success of such programs hinges on robust quality assurance and control (QA/QC). Traditional lab-based testing methods are costly, slow, and inaccessible in many low-resource settings, leading to delays and non-compliance. The iCheck Modular changes the game by making advanced, portable testing solutions available to stakeholders in real-time, enabling immediate quality checks and faster decision-making.

Building on the proven success of BioAnalyt’s iCheck product line, the iCheck Modular introduces modular functionality for integrating new testing parameters as well as advanced processing capabilities. This ensures the device remains highly adaptable and user-friendly, empowering stakeholders such as regulators, millers, and NGOs to monitor fortified foods effectively. Furthermore, the device supports seamless integration with digital traceability systems under development through Gates Foundation initiatives, enabling transparent reporting, risk-based monitoring, and accountability across the food value chain.

By reducing reliance on laboratory infrastructure, the iCheck Modular empowers governments and industries to ensure that fortified foods meet national standards. Its portability, affordability, and ease of use make it accessible across various settings, from production sites to markets and households, strengthening public trust and compliance.

Supported by the Gates Foundation, the development of iCheck Modular not only advances quality assurance in food fortification but also lays the groundwork for integrating safety testing and other nutritional assessments. This groundbreaking device represents a vital leap forward in reducing micronutrient deficiencies, improving global nutrition, and ensuring the long-term sustainability of large-scale food fortification programs.

Rheinstraße 17, 14513 Teltow.

Berlin, Germany